Much of today’s equipment is software and electronics driven, can connect with other machines and systems, and is able to operate autonomously. A comprehensive collaborative manufacturing environment is essential to analyse the impact of a product mix on production, allowing companies to optimise overall throughput. The smart factory is an integral part of the Industry 4.0/5.0 initiative. It is characterised by highly automated processes with minimal human intervention and aims to integrate business and engineering processes, directly linking customer orders to delivery. These goals can only be achieved by information technology from smart intelligent software systems to new and innovative hardware devices, where the objective is to make production processes and decision making more efficient, autonomous, and adaptive using AI, cyber-physical systems, big data IoT.

These processes, resource utilisation, and productivity can then be improved and maximised through qualitative and quantitative data analytics that provides descriptive, predictive, and prescriptive inputs and feedback loops. Such environments clearly require an extensive use of data. Automated processes not only use but also massively create data thus directly becoming additional origins of information besides traditional sources such as planning systems. All this results in an abundance of available data that mirrors industrial processes in unprecedented detail, where AI enables machine learning by using a variety of training models to simulate and infer the status or appearance of objects, that also provides operators and engineers with a new level of insight.

This is why technology enabling big data capture (sensing), analysis (edge and cloud computing), connectivity (IoT), and real-time intelligent monitoring and control (real-time AI model for complex multiple-input and multiple-output MIMO systems) is becoming the new baseline to inspire smart factory, allowing both knowledge-based and data-driven AI techniques to be applied to correct errors and perform predictive control and maintenance to prevent failure without unnecessary interruptions, improving energy efficiency simultaneously.

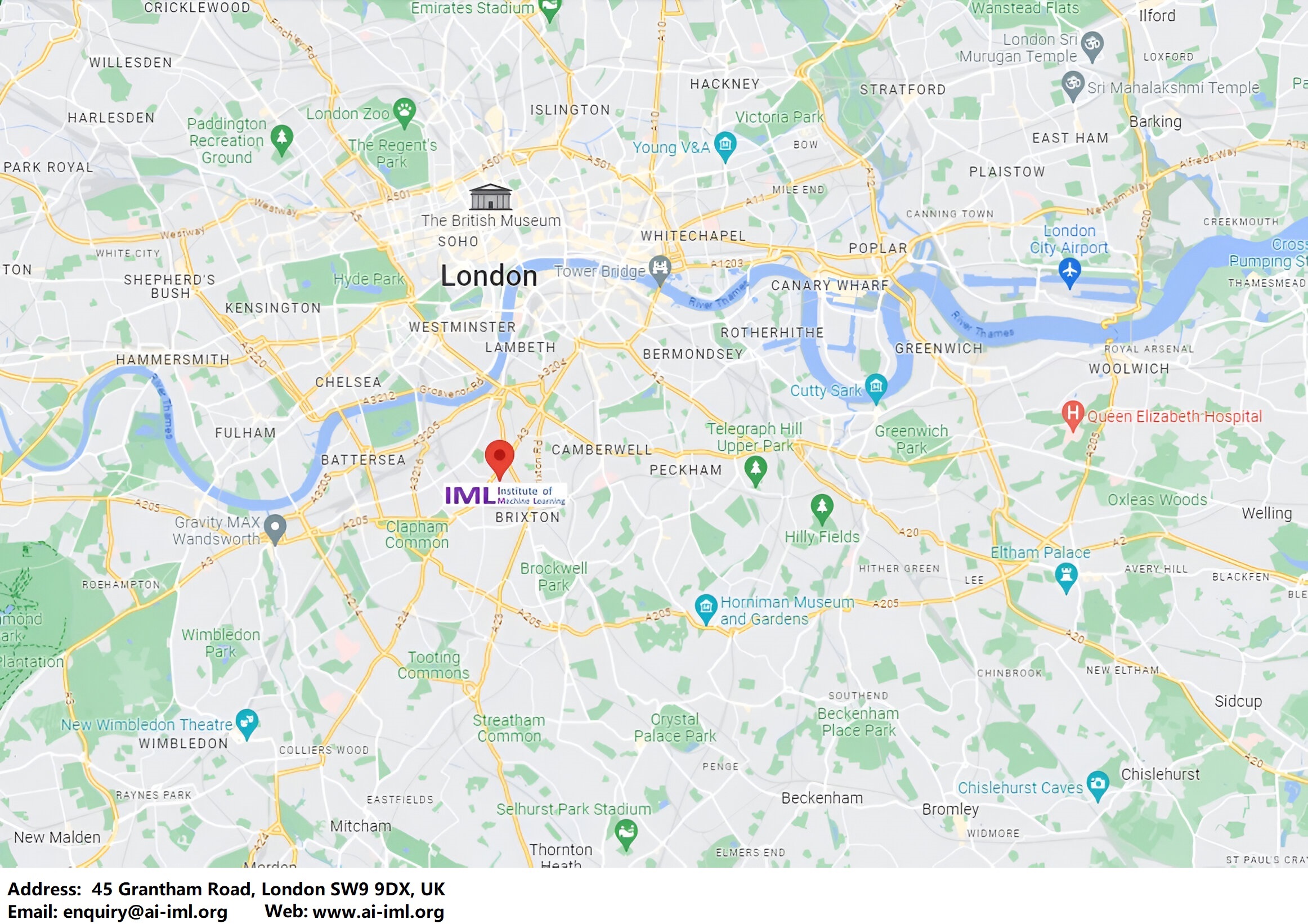

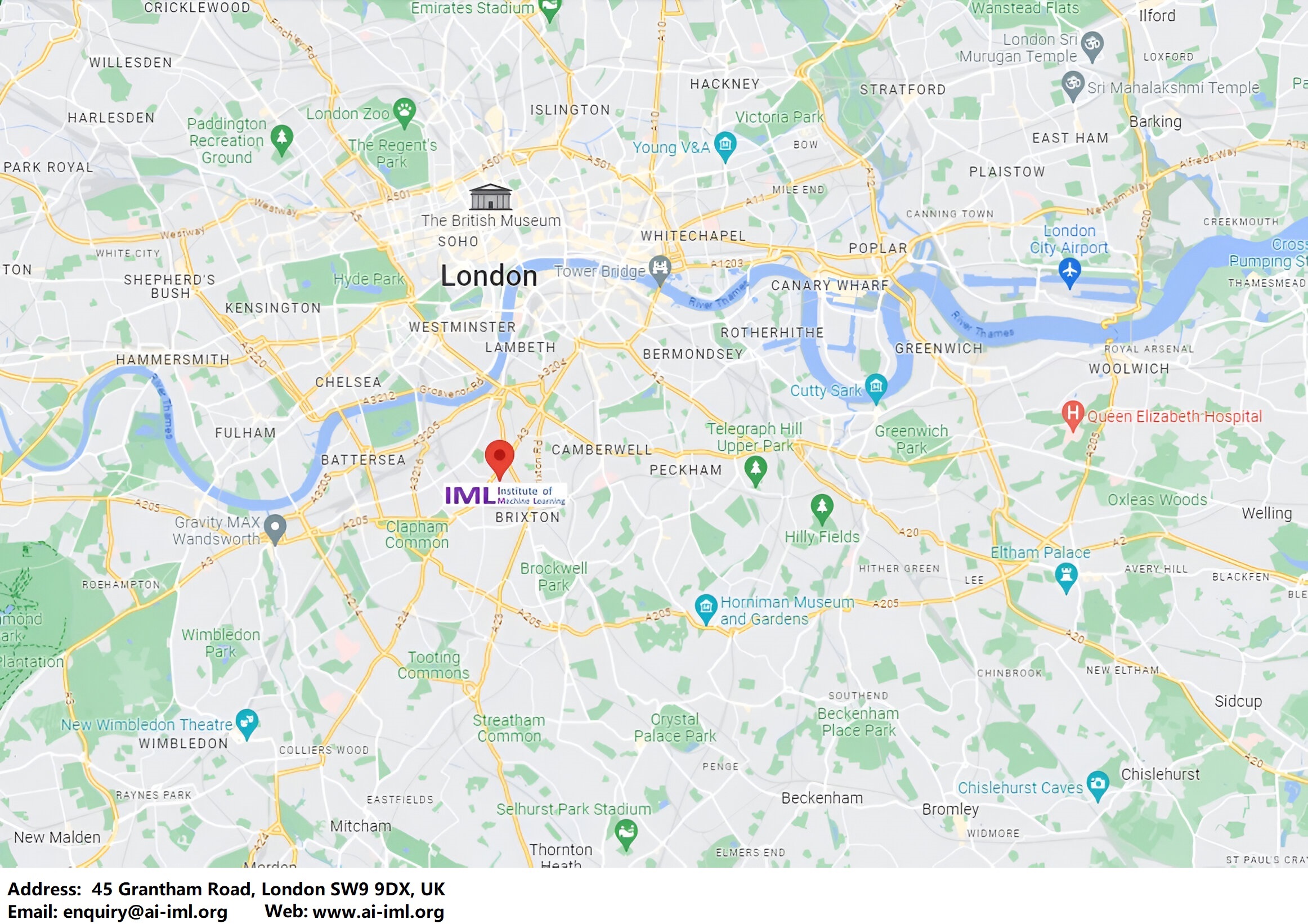

We welcome your comments, discussions, compliments and suggestions. Your inputs/comments can be received by log in to the home page of IML and we will get back to you as soon as whenever it is possible. All enquiries should go to: [email protected].